Exclusive pool house extension

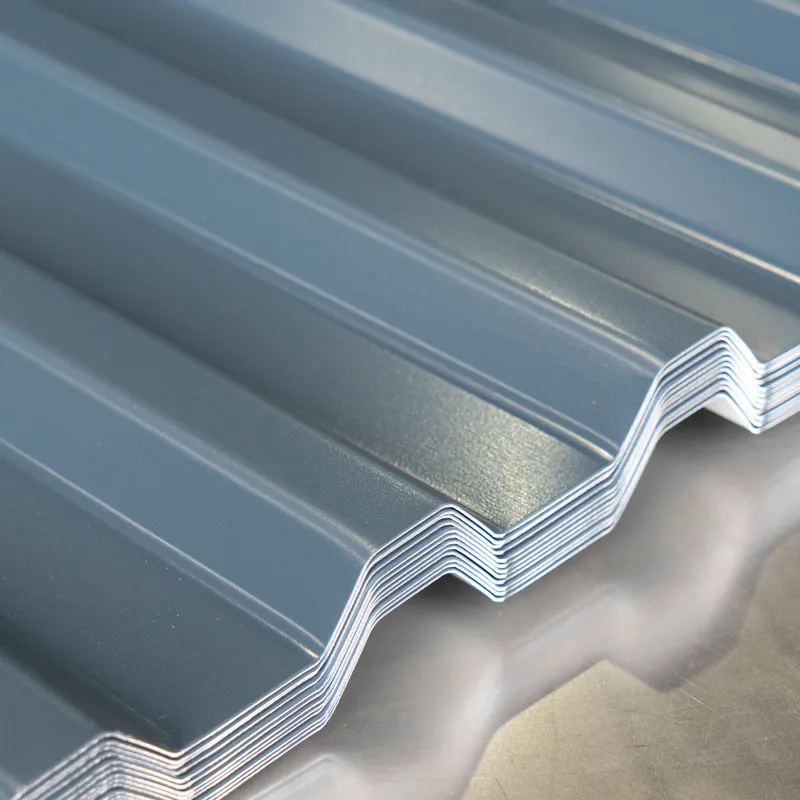

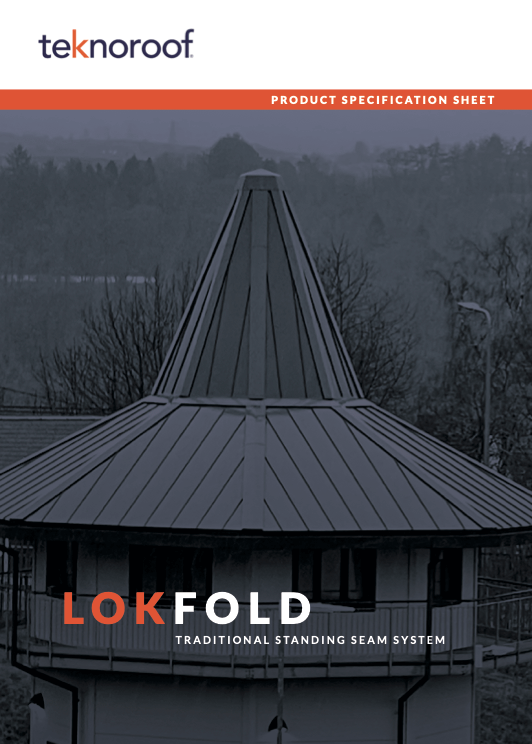

The LOKFOLD looK

fOR THIS RECENT POOL HOUSE EXTENSION OUR CLIENT TURNED TO A METAL ROOFING SOLUTION WITH AN APPEALING FINISH, WHICH WAS EASY TO INSTALL.

Lokfold is the ideal metal roofing solution for home extension projects. For this particular project our customer was keen to have something which offered a contemporary aesthetic. Lokfold more than delivers from this perspective at an enviable price point too.

Flashings and fixings

For all your metal roofing finishing touches, teknoroof has you covered. We’ve extensive experience in providing comprehensive metal roofing solutions, which includes all those finishing details. Thanks to our investment in specialist kit we’re able to offer you bespoke flashing, guttering, fascias and all the fixings you need too.

Need Support?

If you need installation guidance for our Lokfold metal roofing and cladding. At teknoroof we provide specialist support for this particular metal roofing material. Get in touch.

Need a quote?

Contact us via our form here..

PRODUCT HIGHLIGHTS

LOKFOLD is available in a variety of formats from the plain coil to the fully installed system.

Coil

For installers who have their own roll forming capacity, teknoroof can provide coil for this purpose. As major traders in metal products, our buying capacity means that we can provide extremely cost-effective terms.

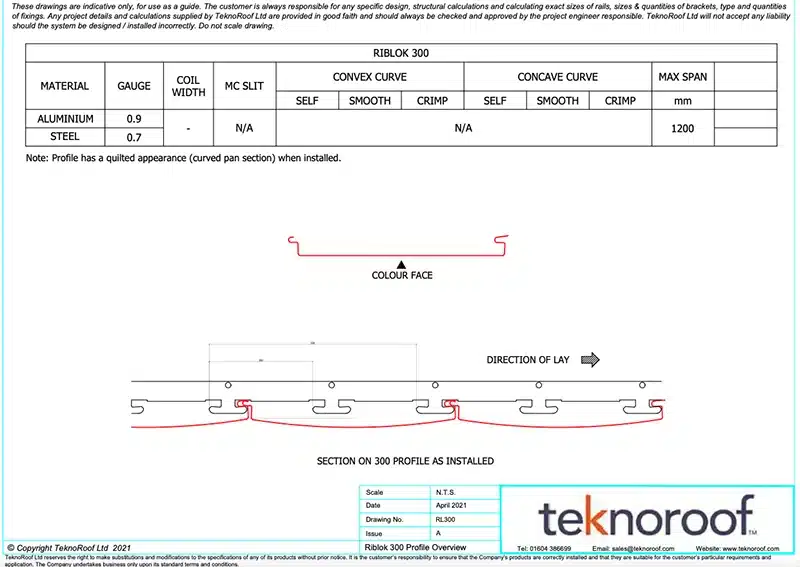

LOKFOLD system

Teknoroof can provide a complete system to roofing contractors including the trays (site or factory rolled), clips and other accessories, together with the sale or rent of specialist tools including seam formers.

Supply and Install

Where required, teknoroof can provide the complete design, supply and installation service using our own team of skilled installers in conjunction with the roofing contractor.

.

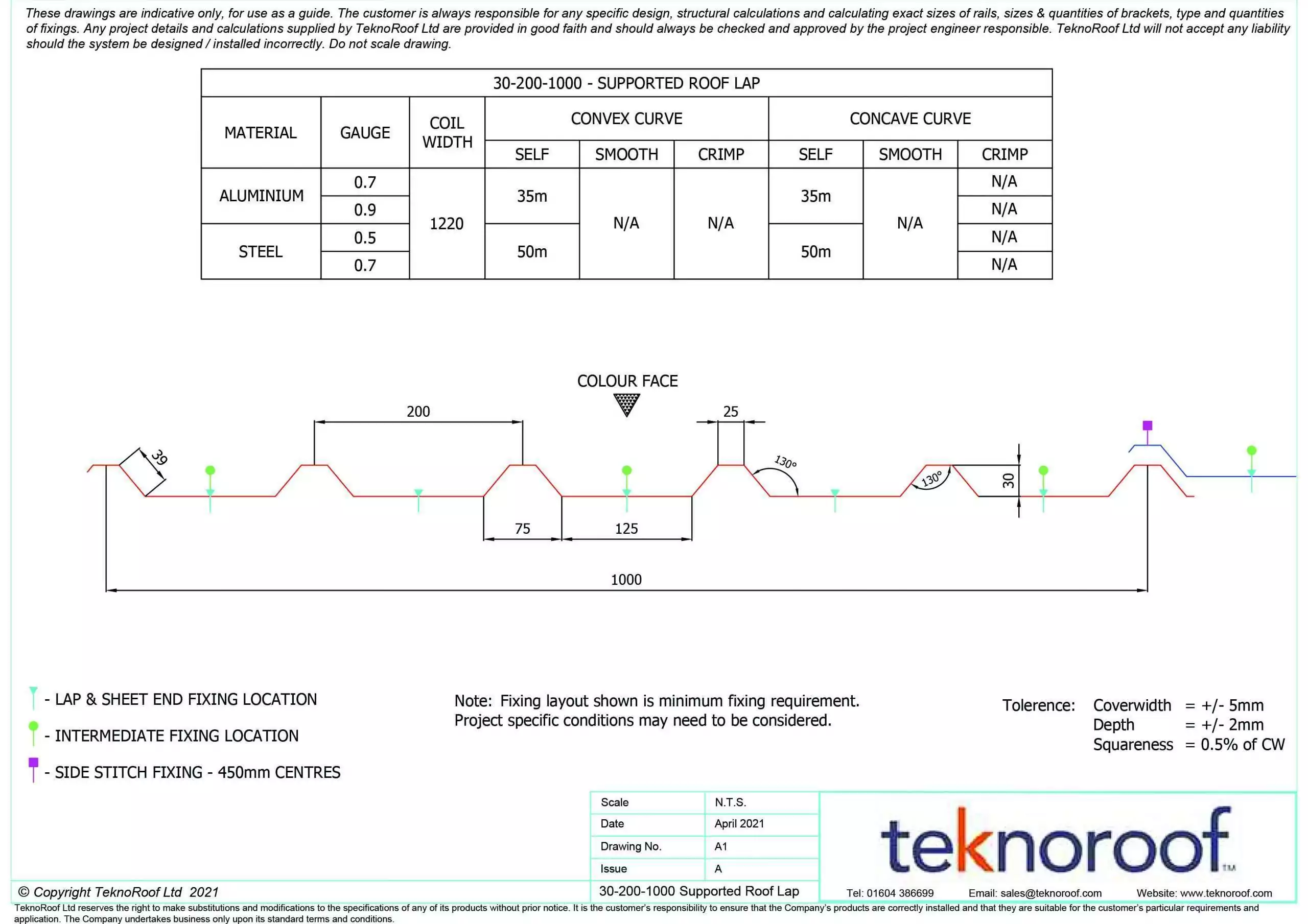

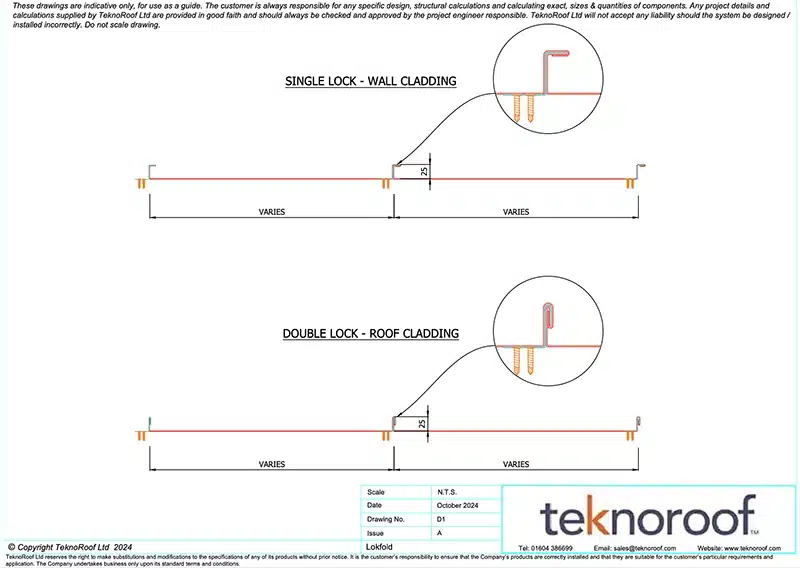

LOKFOLD fixing details

Although there is no technically correct or incorrect end as a start point for a roof, the direction of the prevailing wind should be considered.

In general, each sheet is fixed to the substrate by two fixed clips towards the ridge of the roof, with sliding clips along the length of the slope. The upstand of the next sheet is then laid over and interlocks with the upstand of the tray already in position.

The first fold of the upstand is then formed manually as shown opposite, before mechanical crimping of the upstands using the power seamer.

The sliding clips allow the metal to expand and contract freely along its length. Across the width, the profile of the sheet allows expansion and contraction through a gap at the foot of each standing seam.

Download the brochure for further details

Download the profile